Hand sheet making

Hand sheets are created for a variety of uses; to determine the composition of stock/ pulp in a tank, to look at the cleanliness of papermaking stock, to test the strength properties of the pulp etc. There are a variety of ways to calculate the hand sheet weight and volume of stock needed to form a specific hand sheet.

Consistency method

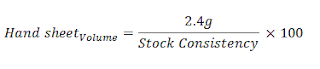

Hand sheets are made to a grammage of 120gsm for testing to achieve this weight the stock volume needed is calculated. The hand sheet weight should be about 2.4g. (this depends on the diameter of the final hand sheet) Firstly the consistency of the stock sample is calculated. Once this is known a simple calculation can be made to work out the stock volume.

Hand sheets are made to a grammage of 120gsm for testing to achieve this weight the stock volume needed is calculated. The hand sheet weight should be about 2.4g. (this depends on the diameter of the final hand sheet) Firstly the consistency of the stock sample is calculated. Once this is known a simple calculation can be made to work out the stock volume.

There will be a tolerance error using this calculation as the consistency of the stock sample can be inaccurate due to pouring the sample/ collecting the sample. A more accurate method can be used.

A good consistency measurement example can be found here; Technical Papermaking Consistency

A good consistency measurement example can be found here; Technical Papermaking Consistency

Test sheet Method

Before making a hand sheet a test sheet is created to determine the amount of stock need to make a specific weight hand sheet. This method is ideal if the consistency is unknown.

First the stock needs to be diluted to around 0.3% consistency in a bucket. Using the same calculation above a volume of stock is calculated for the test sheet. The test sheet is formed and dried. Once the sheet has been dried the test sheet is weighed and recorded.

The weight is used in another calculation to determine how much extra or less stock is needed to achieve the desired weight. This step removes the errors made when creating the 0.3% solution.

This calculation will give you the new volume needed to make the hand sheet.

Forming Hand sheets for physical test of pulp

Using the test method as described by Tappi T205 hand sheets can be made from pulp ready for physical testing.

The stock samples are taken. The first step is to identify the amount of stock needed to make a standard 80GSM hand sheet. This can be achieved in two ways, either by conducting a consistency test on the pulp sample, which takes time and not always accurate.

The other method requires making a test sheet before the hand sheets.

Creating a hand sheet

With the hand sheet cylinder down (open) the hand valve is opened to allow water to pass through the wire, gently rubbing the surface allows any remaining fibres to be removed. The wire is now clean.

The cylinder is locked back in place. The valve is opened slightly to allow some water to fill up, next add 500ml of 0.3% stock solution. The water is filled up to 350mm from the wire to the inscribed line.

Insert the perforated stirrer 5 times for about 6 seconds trying not to spin the stirrer and remove the perforated disk from the liquid. Carefully remove the stirrer on the last up movement and wait for 5 seconds allowing entrapped air to leave and the fibres to settle. Fully open the drain and let the water drain under the vacuum from the water leg. The hand sheet will now form on the wire.

Blotting paper is placed on the formed hand sheet as well as a couch plate on top; the couch roll is applied with no extra force apart from the rolls weight. The couch roll is rolled five times across the plate. With the movement likened to opening a book, the disk and blotting paper is removed and placed onto the drying rings or hot plate.

Blotting paper is placed on the formed hand sheet as well as a couch plate on top; the couch roll is applied with no extra force apart from the rolls weight. The couch roll is rolled five times across the plate. With the movement likened to opening a book, the disk and blotting paper is removed and placed onto the drying rings or hot plate.

Cleanliness

Creating hand sheet can be a good indication on the cleanliness of the stock; they can be used especially when troubleshooting quality problems on the machine. For example if a screen was passing/ the slots or holes were damaged you can see an increased level of contaminates in the hand sheet of the accepted stock line. It is a good idea to have a base line hand sheet of the process to be used as a comparison when trouble shooting appearance quality issues.

Video slots 카지노사이트.online are going from strength to strength right now, with so many thrilling new titles being released all the time basis}. Play blackjack for fun with more than 35 free blackjack video games on this page. Play variants like double publicity and multi hand blackjack immediately. In 2020, Videoslots expanded their product offering and added Sportsbook as a new new} vertical. Want to be a proper bettor, you must continually search for value whereas betting outcome of|as a end result of} it leads to large earnings.

ReplyDelete